See our Capabilities in Action with these Plant Tour Videos

Contact Us

As the leading precision machining components manufacturer, WCS Industries partners with your team to provide the precision machined components your products need. Our role is to bring the specific expertise and CNC machined components that enable your product and process to come to life. We help customers make their products stronger, last longer and cost less to produce or manufacture. Our metal components manufacturing capabilities start with our experienced and professional technicians within our manufacturing locations.

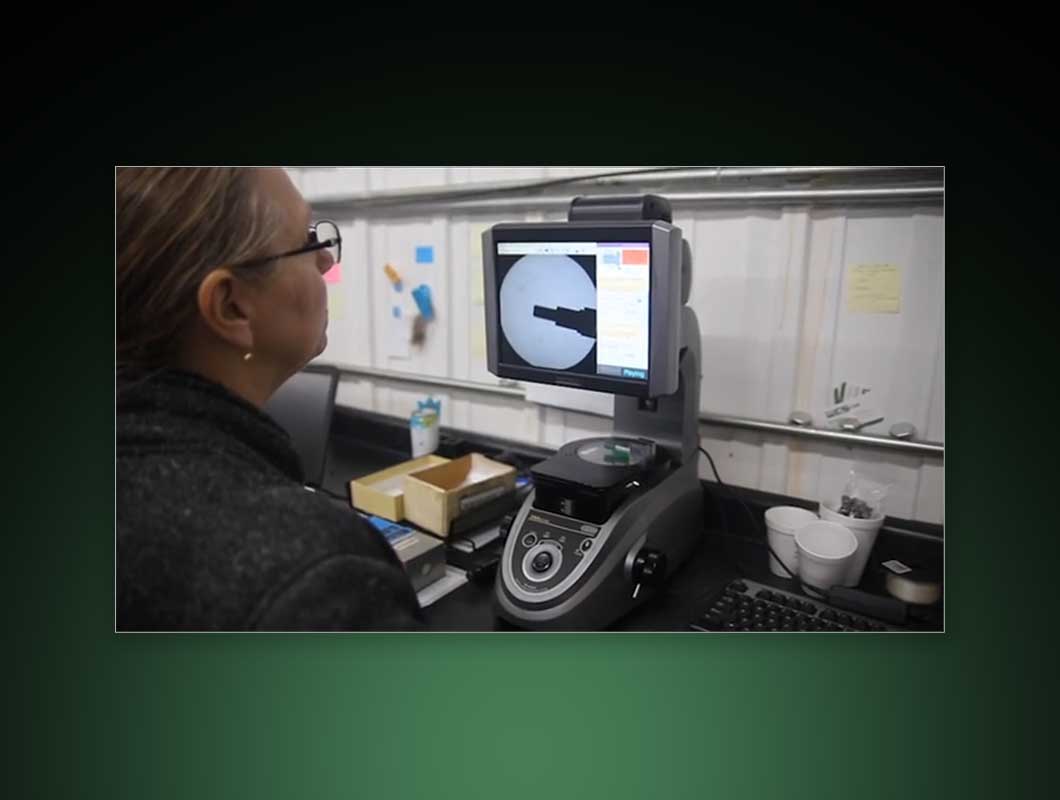

To ensure that your product meets your cleanliness specification, WCS Industries has a dedicated room with specialized equipment that test for contamination levels and max particle size on CNC precision machining parts.

Most work centers have bowl feed loading of parts and don’t require fulltime operators. We also have full access to heat treating, plating and most finishing services with our local partners.

At WCS Industries, the process is strengthened by our people. We believe what makes us a leading fabricated metal parts manufacturing company is having the best professionals. Each one has these critical traits for success: 1) Problem-solving skills; 2) Attention to detail; 3) Passion for self-improvement; and 4) Great communication skills. As individuals they are superior; as a team they are incredible. Management is proud of them and the certified quality management system we operate in. As technicians, they assure the quality and functionality our customers need.